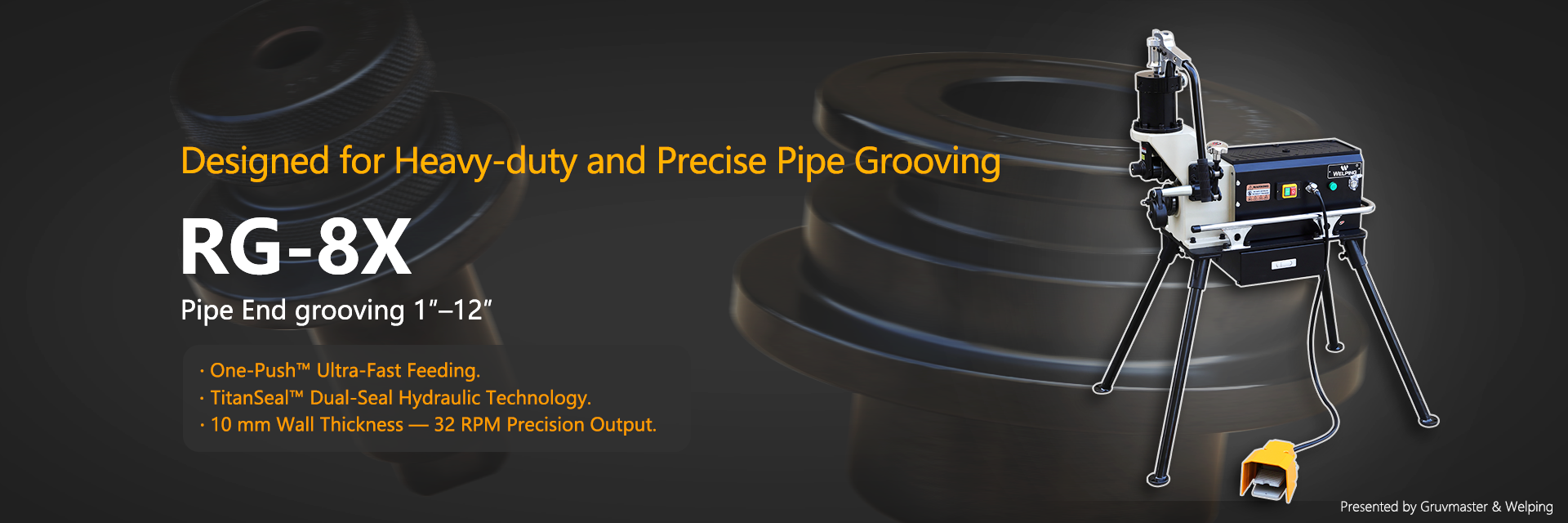

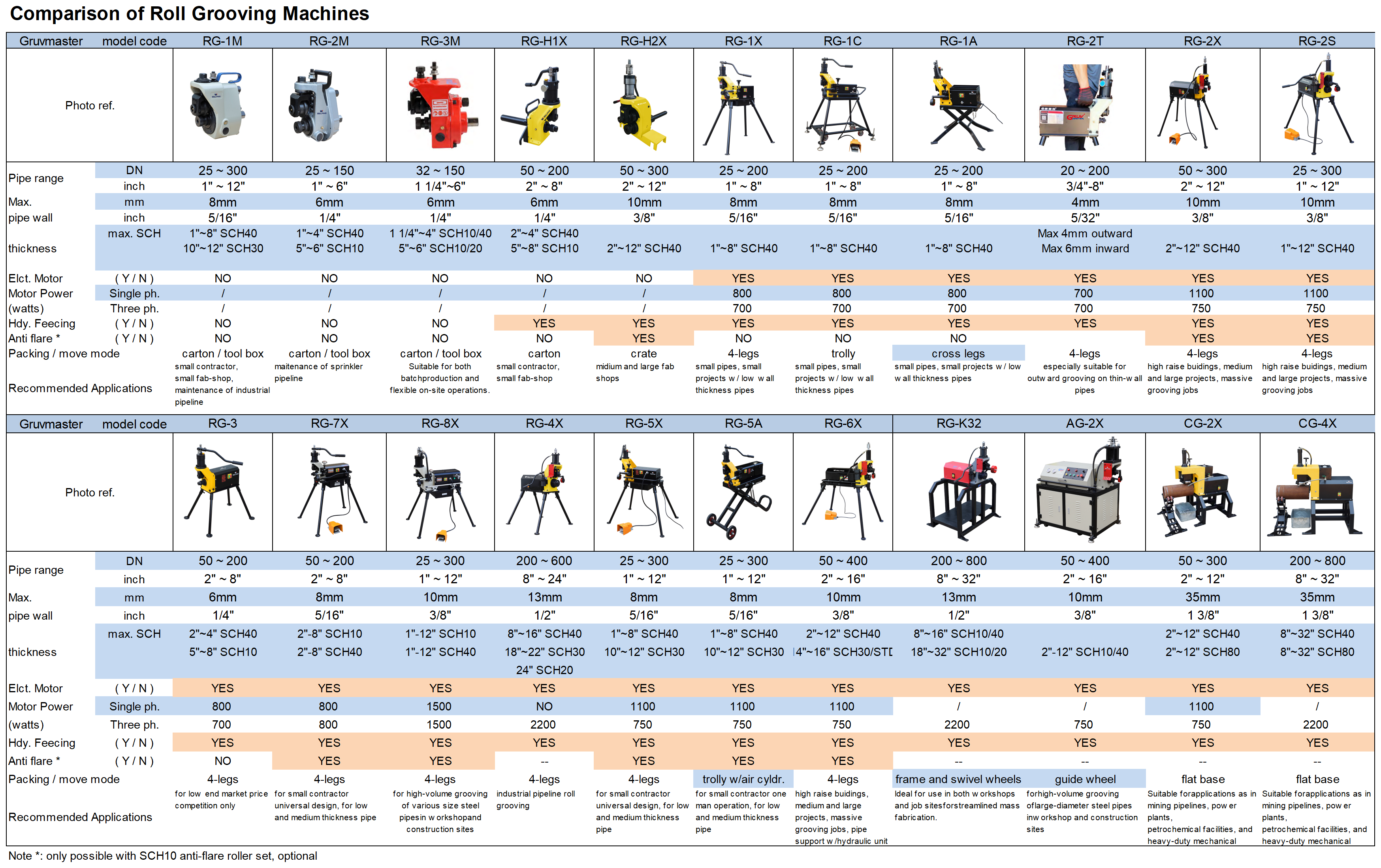

With 10 models available, our hydraulic roll grooving machines cover 1''–12'' pipes. From light-duty to heavy-duty, there’s always a durable and efficient solution to match your specific project needs

Innovative Technology-leading Roll Groovers Manufacturer

Discover Gruvmaster's cutting-edge pipe fabrication solutions:From Roll Grooving to Pipe Cutting, Groove Cutting, and Hole Cutting, our machines offer precision, efficiency, and safety for diverse pipe work needs.

Our heavy-duty hydraulic roll grooving machines cover 8''–32'' pipes with 3 model options. Each size combination is engineered to meet tough demands, ensuring reliable performance and durability in challenging projects

Automatic roll grooving machines with 2 models available, covering pipes up to 24''. Featuring reliable hydraulic control, this series delivers professional efficiency and precision, especially ideal for workshop-based batch operations

Automatic roll grooving machines for pipe fittings, covering 2''–24''. Equipped with a reliable hydraulic control system and exclusive anti-pipe-walk design, ensuring stability, precision, and efficiency in professional workshop operations

Manual roll grooving machines, lightweight and flexible, suitable for independent manual grooving or combined use with power drives and threading machines. A versatile solution designed for portability, ease of use, and reliable performance

Gruvmaster groove cutting machines feature an exclusive structural design, handling pipe sizes up to 32''. Especially suitable for mining pipelines and ultra-thick wall pipes, delivering reliable strength, precision, and long-lasting performance

Groove end reforming machines, designed for correcting pipe fitting flare ends. Perfectly matched with fitting roll grooving machines, ensuring precise reshaping, stable connections, and improved efficiency in professional grooved piping projects

Electric pipe cutting machines with 5 models available, covering 1/2''–20'' pipes. From light-duty to heavy-duty, suitable for steel, stainless steel, copper, and aluminum pipes — always the right cutting solution for you

ABOUT US

New Equipment for Roll Groovers and Cutting Machines

News Center

- Grooving 8"–24" Pipes: Why Structure Matters More Than PowerMar 3,2026Selecting a roll grooving machine for 8"–24" steel pipes requires more than sufficient power. Structural stability, hydraulic consistency, and repeatable groove control become critical at larger diameters. The RG-4X is designed specifically for this range, offering a heavy-duty workshop solution with a split hydraulic system and interlocking roller structure for reliable, consistent grooving performance.

- PTC140 Pipe Cutter: When “Easy to Use” Actually MattersFeb 28,2026The PTC140 pipe cutter is designed for frequent on-site cutting work, focusing on clarity, stability, and ease of use. Its straightforward structure reduces the learning curve and supports smooth, consistent operation. Rather than complex features, PTC140 emphasizes practical usability, making it well suited for construction and maintenance environments where efficiency and reliability matter.

- Both Electric Hydraulic Pipe Cutters: How to Choose Between CM-12 and CM-20Feb 24,2026CM-12 and CM-20 electric hydraulic pipe cutters share the same cutting principle but are designed for different pipe sizes and working environments. CM-12 is optimized for small to medium pipes in workshop use, while CM-20 is built for larger pipes and on-site operations requiring stronger support, stability, and mobility. Choosing depends mainly on pipe size and application needs.