Ridgid 300 vs Gruvmaster RG-1M Roll Groover: A Comparative Analysis

Introduce the topic of pipe working machinery and the importance of selecting the right equipment for specific tasks. Highlight that the article will compare two prominent machines: the Ridgid 300 and the Gruvmaster RG-1M Roll Groover.

Ridgid 300 Roll Groover

Overview:

The Ridgid 300 is a versatile pipe threading machine that can be equipped with various attachments, including a roll groover.

Key Features:

High Quality:

Made from high-quality materials that are durable and strong, ensuring it can withstand long periods of use.

Easy to Operate:

The simple design allows even inexperienced workers to operate it quickly and efficiently.

Wide Range of Applications:

Suitable for a wide range of pipe sizes and applications, making it a versatile tool in any workshop.

Pros:

* Multifunctional capabilities allow for threading, cutting, and grooving.

* Robust construction ensures longevity and reliability.

* Well-known brand with strong customer support and easy access to parts and accessories.

Cons:

* Higher initial cost, especially when including attachments.

* Heavier and less portable compared to dedicated roll groovers.

* May be more than needed if only grooving functionality is required.

Gruvmaster RG-1M Roll Groover

Overview:

The Gruvmaster RG-1M is a dedicated roll groover designed specifically for grooving pipes.

Key Features:

High Efficiency:

Equipped with a high-speed motor that allows for faster groove rolling, improving overall working efficiency.

User-Friendly Design:

Features a non-slip handle and clear scale lines, making it convenient and easy for workers to operate.

Light and Portable:

Compact and lightweight, making it easy to carry and transport, ideal for on-site work.

Pros:

* Dedicated functionality ensures efficient and precise grooving.

* Lightweight and portable design enhances mobility and ease of use.

* Generally more cost-effective for users who only need grooving capabilities.

Cons:

* Limited to grooving; lacks the versatility of the Ridgid 300.

* Might not have the same level of brand recognition

In order to compare the two machines more objectively, the following will display the data of the two, because the operation principle of the two machines is not the same, so the data will be displayed differently.

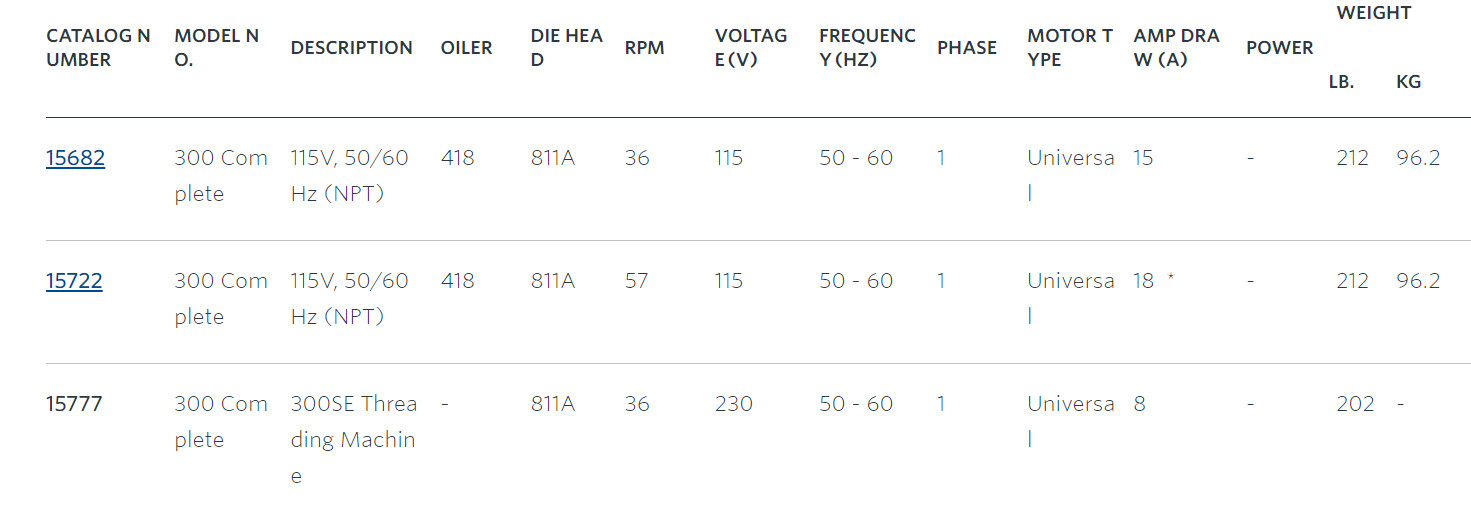

Ridgid 300 Parameter

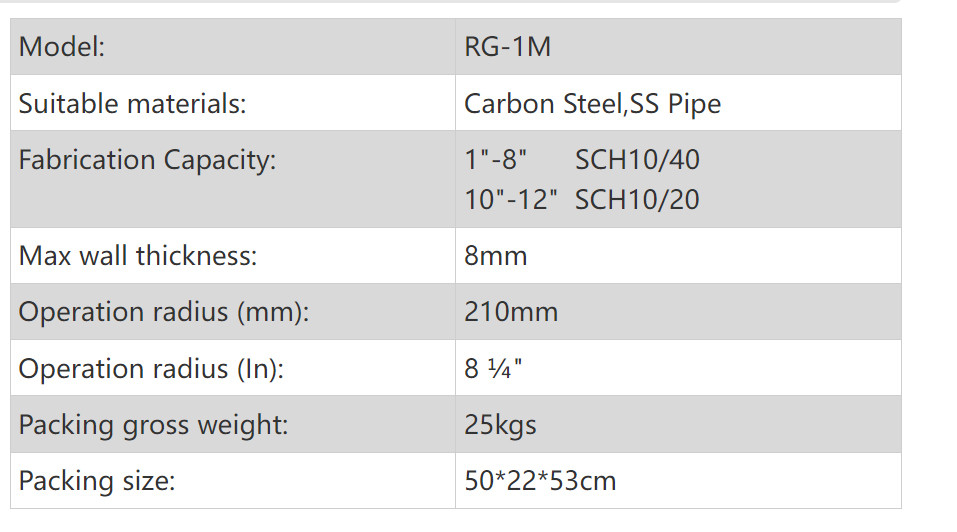

Gruvmaster RG-1M Parameter

Comparative Analysis

| Feature/Aspect | Ridgid 300 | Gruvmaster RG-1M |

|---|---|---|

| Performance | Versatile; high performance in threading, cutting, and grooving. | Superior speed in groove rolling tasks due to high-speed motor. |

| Price | Relatively expensive; higher initial cost. | More affordable; cost-effective for dedicated grooving. |

| Brand Reputation | Well-known brand with strong reputation in the US. | Specialized manufacturer; less widely recognized. |

| User Ratings | High satisfaction for durability and versatility. | Popular for ease of operation and efficiency in groove rolling. |

| Primary Function | Threading, cutting, and grooving. | Dedicated pipe grooving. |

| Ease of Use | Generally user-friendly with straightforward operation. | Designed for ease of operation with non-slip handle and clear scale lines. |

| Portability | Heavier and less portable. | Lightweight and portable; easy to transport. |

| Applications | Wide range of pipe sizes and applications. | Specific focus on groove rolling tasks. |

Summary

Ridgid 300: Offers versatility and durability across multiple functions, suitable for various applications but comes at a higher price.

Gruvmaster RG-1M: Specializes in efficient groove rolling, providing cost-effective and portable solutions for dedicated grooving tasks.